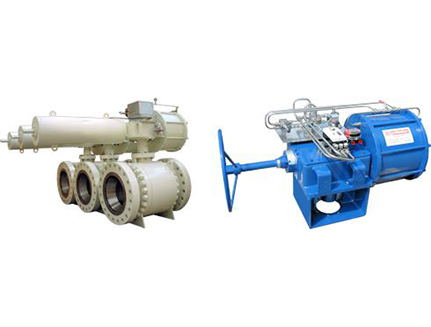

Quarter-Turn Scotch-Yoke Valve Actuators

Overview

PN and HY-Series pneumatic and hydraulic scotch-yoke valve actuators have been designed specifically to guarantee long cycle life in the most demanding applications and environmental conditions. A fabricated steel frame, coupled with an all-steel construction, results in lighter and more corrosion resistant scotch-yoke valve actuators than traditional designs employing castings. A light design, superior corrosion resistance and an Ingress Protection rating of IP66 as standard make PN & HY-Series scotch-yoke valve actuators an ideal choice for offshore applications, or any other in which weight and corrosion resistance are critical design considerations.

Applications

Automation of any quarter-turn mechanism; including ball, butterfly & plug valves and louvers & dampers.

Operating Ranges

Supply Pressures

PN-Series: 2.7 to 12 Barg (40 to 174 psig)

HY-Series: 13 to 250 Barg (189 to 3,625 psig)

Torque Outputs

200 to 680,000 Nm (1,770 to 6,018,000 lb in)

Temperatures

Ultra-low: -65 to +80°C (-85 to +176°F) (HY-Series only)

Low: -45 to +60°C (-49 to +140°F)

Standard: -20 to +80°C (-4 to 176°F)

High: -20 to +140°C (-4 to +284°F)

Key Features & Benefits

Third party approved for use in SIL 3 certified systems

Electroless nickel plated cylinder as standard with hard chromium plating, Xylan® or Electro-film available

Springs contained within a fully welded canister (which is post weld heat treated) to guarantee simple and safe removal

Springs are scragged (set removal) in order to warrant optimum and stable output torque characteristics

Easy and economical maintenance due to simplified design, no special tools required

Compliant to PED 97/23/EC

Modular construction means greater flexibility when selecting cylinder/spring combinations, and reduces production downtime during field servicing

Various scotch-yoke configurations (symmetrical, demi-canted and canted) allows for optimum and cost effective valve actuator sizing

Suitable for high frequency and high speed operation

Guide bar frame design used to eliminate side forces and low friction seals ensure high efficiency, even at low supply pressures